THE FYI ON TPI: KNOW YOUR TIRE’S CASING

May 12, 2022

If you’ve ever shopped for bikes tires, you may have noticed a “TPI” number on the packaging or spec sheet. What does TPI mean, and why does it matter when choosing tires? Teravail product manager Zane Bushey answers some of the most frequently asked TPI questions:

First things first: what does TPI stand for?

Threads Per Inch, or the number of threads per square inch used in a tire’s casing.

What are the threads made of?

Vulcanized rubber tires typically use nylon threads in their casing.

Why should riders care about the TPI of a tire?

TPI influences tire performance and is an important factor when selecting the right casing for your riding style.

How is TPI measured?

You measure TPI by counting the number of thread crossings in one square inch of the tire casing fabric. This is difficult to see when the tire is coated in rubber, but obvious when looking at the raw tire casing.

How does a higher TPI change the characteristics of a tire?

Generally, higher-TPI tires are lightweight and supple, leading to lower rolling resistance. But many higher TPI tires sacrifice puncture protection, sidewall stability, and tubeless reliability. Also, a TPI number does not tell the whole story; most manufacturers add a mix of sidewall protection, puncture protection, bottom-out support, or tubeless-ready support to optimize performance.

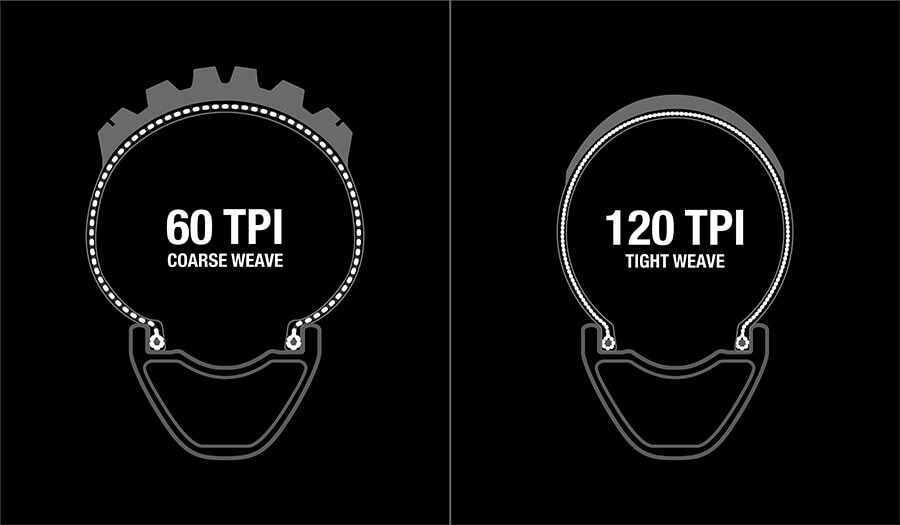

How much does the size/diameter of the threads affect the characteristics of a tire?

Lower-TPI tires often use larger nylon threads and a more open weave. This open and coarse weave requires more casing rubber in the manufacturing process and a stiffer, heavier, more durable casing. higher-TPI casings have a tighter weave with less rubber for a lighter, more compliant casing.

Does TPI affect the amount of rubber used?

Yes. Lower-TPI casings use larger-diameter nylon with an open weave. This open weave means more gaps, so more rubber goes into the casing construction to fill them. High-TPI casings use finer nylon and a tighter weave, requiring less rubber to fill in the gaps.

Does TPI affect a tire’s puncture protection?

Yes. Lower-TPI tires use thicker rubber and nylon, providing extra puncture protection. Many tire makers add a nylon/polymer weave under the tread cap of higher-TPI tires to improve puncture resistance. This offers the benefits of a high-TPI casing without sacrificing durability.

How does TPI translate across different manufacturers? For example, will a 60 TPI tire from one manufacturer generally have the same qualities as a 60 TPI tire from another manufacturer?

TPI is generally consistent across manufacturers at the raw-material stage. Brands start to diverge as they turn these raw materials into casing plies, and then tires, that follow their design philosophy.

When shopping for tires, how should TPI factor into the decision-making process? Is there an ideal TPI for gravel tires versus MTB tires? Do personal preference and riding style factor in?

When shopping for tires, it's essential to be aware of low-TPI casings and their intended use case.

- Most tires below 50 TPI have a non-folding bead, making them unsuitable for tubeless setups.

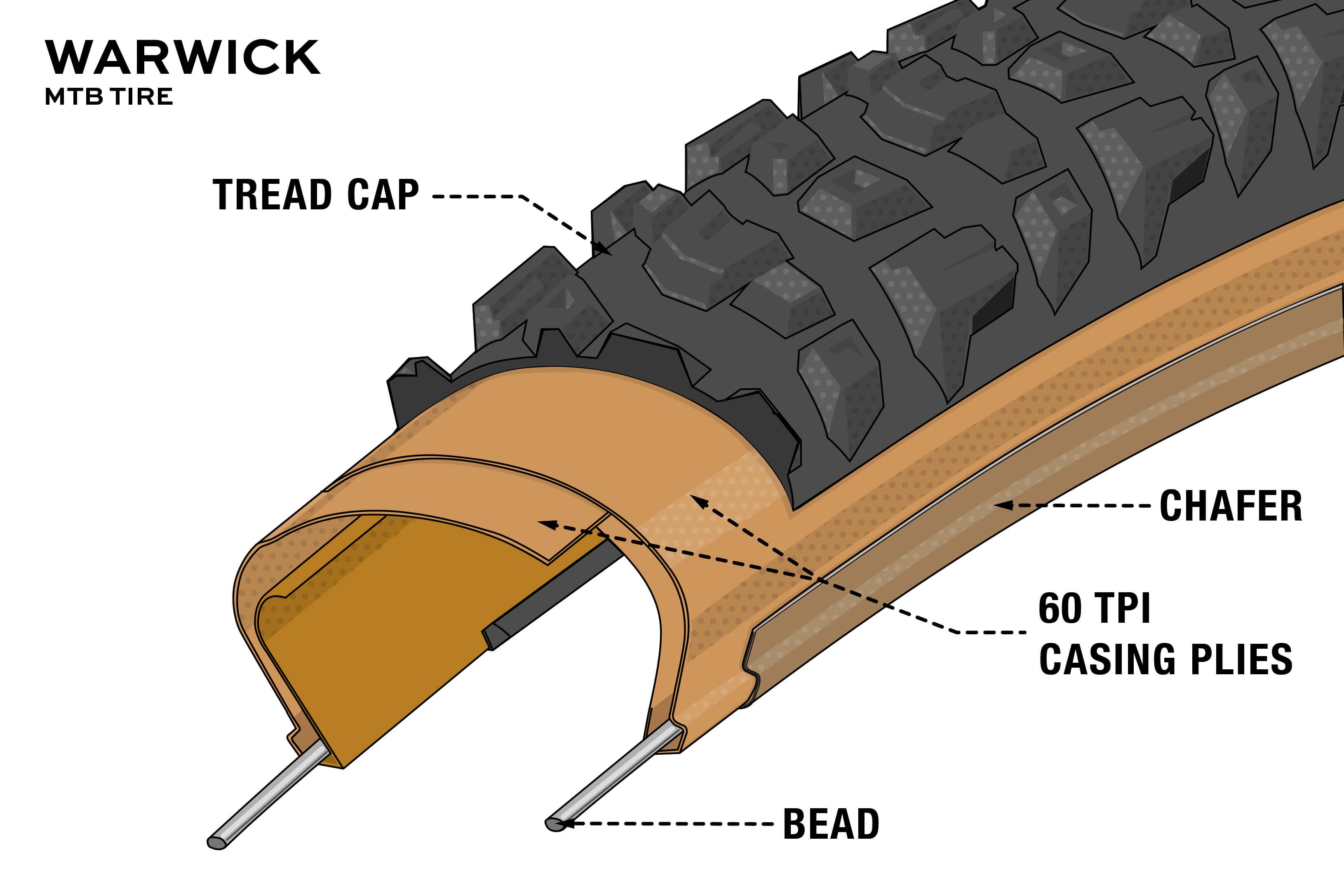

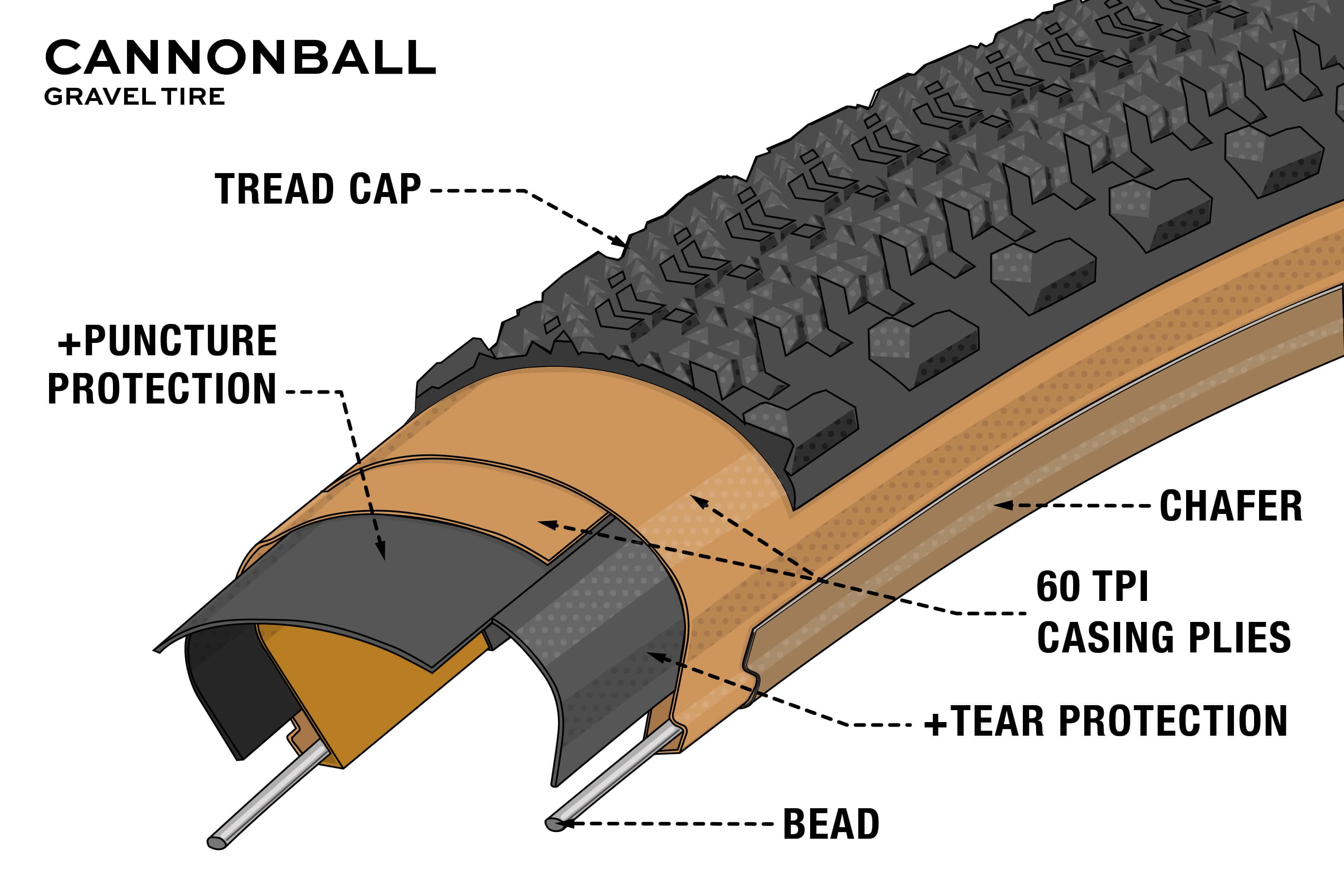

- 60 TPI tires are popular for gravel and MTB, as they strike a nice balance of ride comfort, durability, and tubeless reliability.

- 120 TPI tires are still common in MTB racing and the lower-volume road and gravel category. The extra compliance of a high-TPI casing is especially noticeable on lower-volume tires with smaller contact patches.

Remember that TPI is only one attribute of a tire’s layup. A casing’s configuration, sidewall protection, and puncture protection schemes all affect performance. For example, both our Light and Supple and Durable gravel tires use a one-ply 60 TPI casing. However, the Durable version uses a bead-to-bead protection layer to prevent sidewall lacerations and punctures. Although both have the same TPI and base casing, they each have unique characteristics tuned for certain riding styles and terrain.

If someone is primarily concerned about getting more mileage/better durability, what should they consider in relation to TPI?

If you see a high TPI count, dig a bit deeper to find out whether it's a performance-focused layup or the casing has supplemental sidewall or puncture protection. The tire’s protective layers, rubber compound, and intended use case have more influence on longevity than TPI alone.

If someone is primarily concerned about performance and handling, what should they consider in relation to TPI?

If you focus on weight and rolling resistance, you'll want tires with a 60-TPI or higher casing. That said, TPI is only part of the equation. A high TPI (120+) was once the primary indicator of a race-oriented tire casing, but this has shifted as tire casing plays a more structural role in tubeless tires — especially in the MTB category.

Always look at a tire's intended use case outlined by the manufacturer, and consider the layers of puncture protection, sidewall protection, and rubber compound.

Now you know the what and why behind TPI, which will come in handy next time you’re searching for the perfect tires. Need a new set soon? Take a look at our gravel, all-road, off-road, and fat & plus offerings. Want more tire knowledge? Read our Bike Tire Size Guide to learn how to choose the ideal tire size for your bike and riding style.