HOW IT’S MADE: THE TERAVAIL DESIGN PHILOSOPHY

June 1, 2022

What makes Teravail tires different from the rest? Part of it is our unique approach to problem solving, design, and construction. If you’ve ever wondered how your tires go from rough idea to rubber, our product and design teams explain it all. Read on.

What is your name and job title? What do you do in your role?

Zane Bushey, product manager. My job is all about working with our brand team worldwide as we develop new products (okay, it's mostly tires), but it’s a full-time gig!

Bailey Van Etten, industrial designer. The short answer is that I am responsible for the aesthetics of our products — it’s my job to make stuff look cool. The long answer is that I work with engineers, marketing, and product managers to help build products that work as good as they look. For example, if we want a fast-rolling tire, I work with Cory to figure out what knobs I can turn to achieve the desired performance in a way that also screams “I WANNA GO FAST!!!”.

Cory Rand, design engineer. I work with factories to turn Bailey’s drawings into actual tires. Where Bailey looks at the design from an aesthetic perspective, I look at it from a technical perspective. For example, I dictate the casing profile, the material construction, and the general profile of the tire.

Tell us a little bit of the history behind Teravail. What led to the creation of the brand?

ZB: The brand started around 2015 when gravel endurance events were gaining popularity around North America. A few of the early members of the Teravail team were participating in these events and pushing the limits of their equipment, especially tires.

They saw an opportunity to combine the durability of what was traditionally a touring tire and the tread features of a cyclocross or MTB tire. This first tread design (later named Sparwood) was built to thrive in events like the Tour Divide, where durability is essential and tread features must deliver control in dirt, loose gravel, and even singletrack. While the brand has evolved to a broader focus than a single event or category, we still champion this experience-based design approach.

Design

What prompts the decision to create a new tire?

ZB: There is no single catalyst that prompts a new product. Our projects usually revolve around team and rider feedback, development trends, and continuous R&D. We're always documenting ride impressions, experimenting with new layups, tread design concepts, and testing products in the market to see what we can learn by pushing our boundaries or refining a current design.

BVE: Many new ideas come from a desire to experiment with solutions for the problems we've all had with existing tires. I keep those ideas active and in the open, and others on the team will say, “This project would be a great time to work through X/Y/Z ideas.”

CR: Sometimes we'll ideate on how to take advantage of new technology that our manufacturing partners develop. As a younger company, there are many new avenues for us to explore. It can be more challenging to stick to one new project rather than take it all on at once.

How does the process start?

ZB: Usually, we identify a gap — be it a gap in product performance or tire fit for a new bike or riding style. We often find these gaps when connecting with riders or when we're out testing products. From there, our industrial design, engineering, marketing, and sales teams work together to validate project opportunities and prioritize development. For example, industrial designers and engineers establish design boundaries and potential directions that might elevate a tire's performance.

BVE: Lucky for me, a lot of ideation starts with my own riding experiences. It's important to get tires on the ground and experience how different things behave in different conditions, but I also talk to other riders on the trail to learn about their experiences and opinions. This is crucial for making sure that riders perceive our designs the way we expect them to.

CR: Looking at our prototypes and competitors' products, we can create a feature set that is most important for a given design. Because we have access to many experienced riders, we can do a lot of ride testing in house.

What factors do you consider when creating a new tread design?

ZB: We anchor our design process around a focused ride experience and a certain terrain type. First, we align on target terrain and ride experience. Then, our industrial design and engineering teams choose relevant product benchmarks from the market. We analyze benchmarks, conduct back-to-back ride tests, and collect rider feedback. This testing and benchmarking work helps us set the boundaries of the project. The boundaries and target attributes range from quantifiable (weight, lug height, or tread distribution) to qualitative, (visual theme, color, texture, and fit within our current lineup).

How do you determine what types of tread features to use, and where to place those features?

ZB: The tires in any given category often have similar tread features. Yet, nuanced differences in scale, distribution, or geometry can impact product performance. Our benchmarking process helps us understand the fundamental design philosophy behind the category's top-performing product. Then, our engineering and industrial design teams look to improve upon it or define a new approach to the problem. Sketches and 3D-printed prototypes make it easy to explore many concepts early in the project.

At what stage of the process do you decide what compound to use?

ZB: We have an idea of our target durometer in a project's sketch phase, but we validate that assumption in the test phase. We start with an idea of the compound most other tires are using for the specific terrain or use case. For example, we build our gravel tires with a 60a durometer, as it balances durability with compliance and rebound for grip on rocky, uneven surfaces. However, we can test other compounds in the prototyping phase, as a new design philosophy or tread volume might benefit from different attributes.

Testing

How do you test a new design?

ZB: We finalize tooling once we've committed to a 3D form (validated through benchmarking). Once we cut a mold, we're committed to a single tread shape for that round of prototyping. That said, we can still adjust casing layup, casing plies, supportive inserts, and rubber compounds. This lets us document the effects on the tire's performance through back-to-back testing.

How many potential designs might you typically end up testing?

ZB: We usually review three to five concepts before committing to a tire mold. Once the tire mold is cut, we review three to five different combinations of casing structure and tread rubber. Sometimes, none of the prototypes meet our design targets, so we cut new molds and repeat the evaluation process, documenting what we learned along the way.

How many rounds of testing is typical for a tire?

ZB: We plan for three rounds of formal ride testing. The first round consists of comparing market benchmarks and prototypes based on our existing tooling. The second round provides casing and layup information, compound refinement, and tread design validation and comparison to the initial benchmarks. The final round of testing is confirmation of the updated layup’s pre-production spec.

How do you determine whether a design is a “winner,” needs more refinement, or just won’t work?

ZB: Our evaluation process is always evolving. If we've documented our benchmarks and the target use case and terrain for a project, we have an excellent basis for evaluating prototypes. We're enrolling more test riders beyond our team to help validate prototypes and offer feedback based on their local terrain and riding style. Ask us in a year, and we will likely have a slightly different approach. The theme is incorporating more feedback earlier to deliver a product that elevates the ride experience.

How long does the process take from concept to finished product? Do some types of tires take longer than others?

ZB: The supply chain is the most significant variable. Most projects take from 18 to 36 months, depending on complexity and our experience in the category.

In a broad sense, what types of design features should someone look for when choosing tires for:

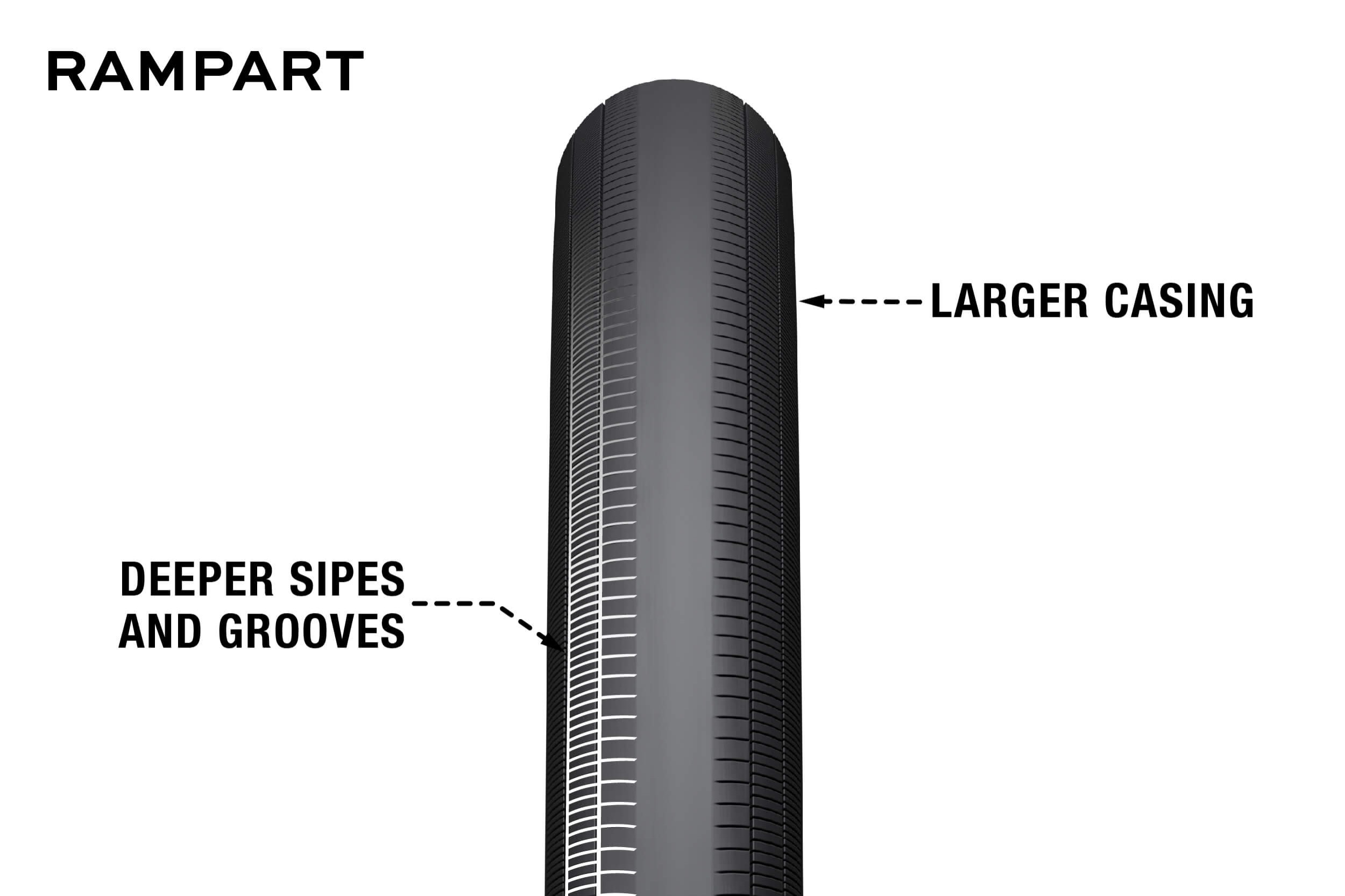

Road

Road tires have smooth center treads, often with slight sipes or textures on the shoulder for traction when cornering through road debris.

- Larger casing to improve ride feel and absorb vibration

- The transition and shoulder, or edge of the tire, features sipes and grooves for more compliance in the tread when cornering or riding over uneven terrain

Gravel

Tread design depends on intended gravel type. Gravel is a general term, and there are so many types of unpaved road surfaces with varying levels of rock, sand, and maintenance.

Tires designed for dry and hardpacked gravel have many features that align with all-road tires.

- Grooves or low lugs in the shoulder area shed debris and keep you in control through loose corners

Tires designed for loose, dry gravel use heavier tread features.

- Biting edges on the leading and trailing sides of lugs, even in the center of the tire

- Open transition area and shoulder lugs that stand proud for better support when cornering at speed through loose conditions

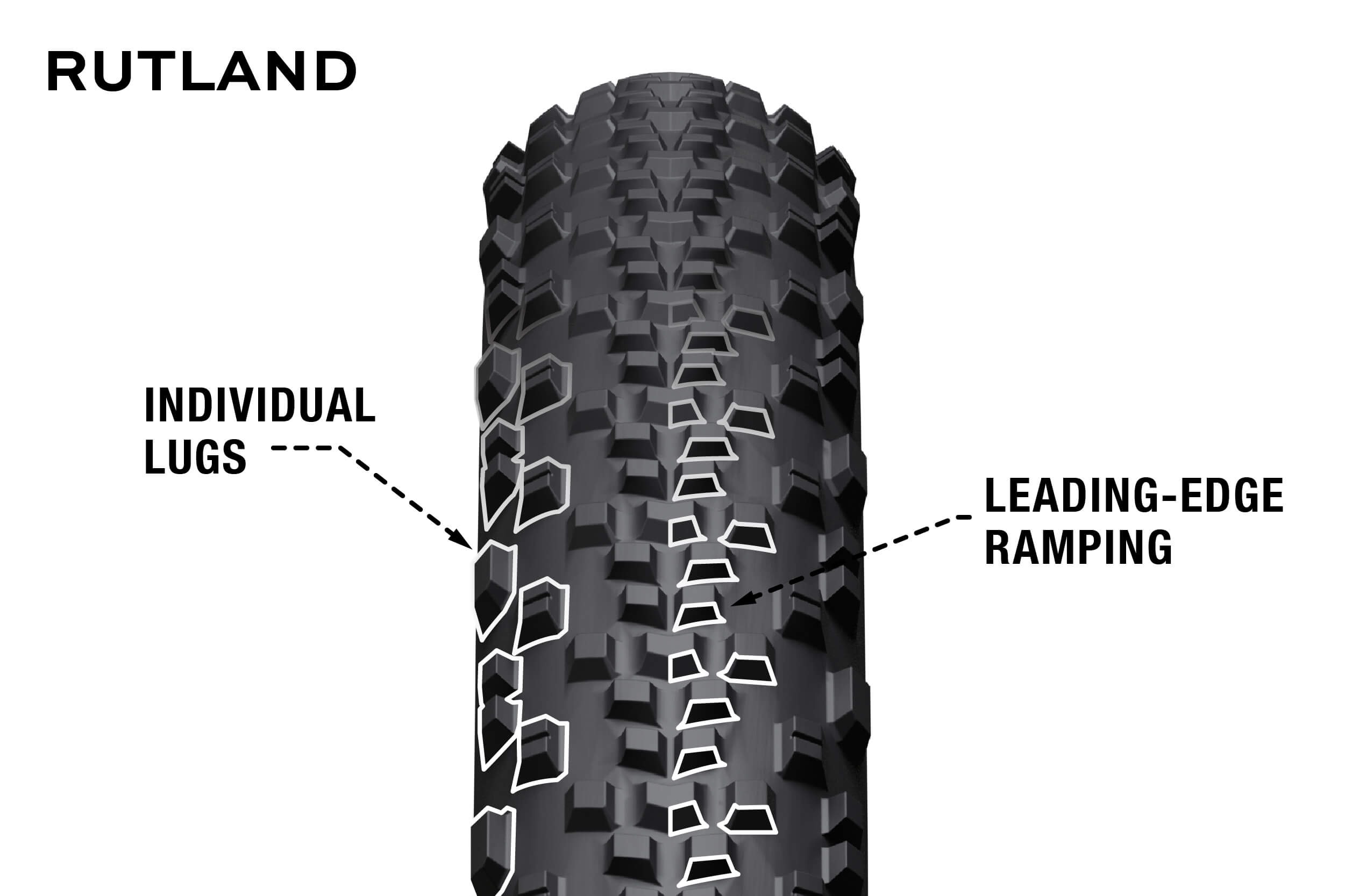

Gravel tires designed to flex into wet or mixed terrain, including singletrack, look like mini-MTB tires.

- You can identify individual lugs on the tire, each with biting edges

- Open tread space to clear out mud and rock buildup

- Leading-edge ramping and tight lug spacing in the center preserve rolling efficiency

Bikepacking

Bikepacking tires require balance. Larger cross-section or higher-volume tires provide additional comfort and control on a loaded bike; larger MTB tires are a popular choice. However, rolling efficiency is essential, especially if a route includes paved sections or extended two-tracks.

- Low, ramped center lugs for efficient straight-line rolling

- Large shoulder lugs to help keep everything on the rails through the unexpected

Mountain

Mountain, like gravel, has many subcategories.

XC and light trail tires aim to minimize rolling resistance with side lugs to keep you upright in corners.

- Low, evenly distributed lugs optimized provide adequate traction without compromising weight or rolling efficiency

Trail and aggressive trail tires are designed for mechanical traction in dirt and rock.

- More open tread pattern

- Fewer, taller lugs

Enduro and downhill tires are oriented to provide maximum traction in specific conditions and at high speed.

- Central lugs are large and blocky to provide maximum traction

- Substantive shoulder lugs for high-speed cornering

Thanks for reading — we hope you learned something. We love designing tires and we think you’ll love riding them. If you need a new pair, take a look at our gravel, all-road, off-road, and fat & plus lineups.